Maximising the returns from growing biomass

by Michael Doran, business development manager of Rural Generation Limited

Farmers should not expect to find that simply growing energy crops will

prove very profitable. They must also use such crops to meet needs

besides those for heat and power which people will pay them to fill.

Rural Generation is a small private limited

company formed in 1996 by John Gilliland, the

current President of the Ulster Farmers Union,

to commercialise an R & D project undertaken

by the Department of Agriculture in Northern

Ireland involving gasifying willow chip to produce

heat and power. Mr. Gilliland had been

looking at alternative land uses from the 1990s

and had planted some willow coppice in 1994

in association with the Horticulture and Plant

Breeding Station at Loughgall, Co. Armagh, on

his Brook Hall Estate in Co Derry. Further

plantings have taken place since and we now

have 45 hectares of which 15 hectares are harvested

each year.

Willows may be planted from March to June,

and planting can be by hand or by automatic

planter, which is normal on areas greater than

one acre.

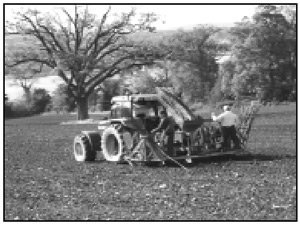

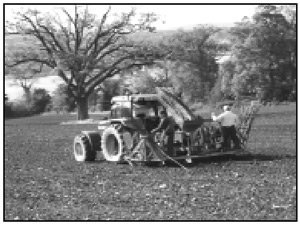

|

| Planting Willows |

The planter shown is capable of planting

four rows at a time. Willows are usually

planted in double rows, with cuttings 70cm

apart in each row, with a space of 1.4m between

double rows. A cutting 20cm long is taken from

a rod approximately 3m long. The cutting is put

into the ground vertically without an established

root system. Cuttings are usually planted

at 14,000 to the hectare.

Willows will grow in most soils, except highly

organic. Ground preparation is important, and

includes ploughing, power harrow and rolling.

Rabbit fencing is critical for the first six months

of growth, until the willows are established. The

only pest that is likely to cause problems at the

early stage is the leatherjacket, which will eat

the cuttings unless treated.

Typically in the first year the willows will grow

to a height of approximately 1.5m. They will

grow as a single stem. It is normal to mix 5 or 6

different clonal types when planting. Willows

are susceptible to attack by rust, which will

affect the leaves. While rust will not actually

kill the plant it will effectively destroy the willows'

ability to transpire through the leaf and

will severely stunt growth. The use of polyclonal

types will completely eradicate damage

from rust.

In the winter at the end of the first year of

growth the willows are cut back to ground level,

usually using a finger bar mower.

When the

plant re-grows in spring of the second year it

will "multi-shoot" and 5 or 6 stems will be

reproduced from the original single stem plant.

|

| Willows on Brook Hall Estate |

This coppicing is done to increase the yield.

After cut back the willow will usually grow 3-

4m in the first year. It will continue to grow for

another two years after which time it is harvested.

Further harvesting usually takes place every

three years. This has been found to provide the

best yield because if crops are harvested every

one or two years their bulk yield is small while

past year three, the percentage increase in bulk

yield is marginal.

At Brook Hall Estate we use a modified Claas

forage harvester that makes chip. This is fed

directly into trailers and taken back to the farmyard.

Our willow normally yields approximately

30 dry tonnes of chip per hectare per harvest.

As the harvest is only done every three years

this equates to 10 dry tonnes per hectare per

annum. The harvester can cut up to 8 hectares

per day in good conditions. Even though the

harvesting is usually carried out in January or

February the ground tends to be dry as a result

of the willow establishment.

Traditionally willow is harvested by rod. This

can be carried out by using a strimmer, or by a

mechanical rod harvester. The main benefit of

rod harvesting is that is avoids the necessity for

drying the willow before combustion. At harvest

time willow is usually about 55% moisture

content. If chipped, the chips will have to be

dried or the biomass will effectively create a

compost heap, with a considerable loss of combustible material. If rod harvested, the rods can

be stacked at the end of the field, and by early

summer they will have dried naturally to

approximately 35% moisture content without

any degradation of the fuel.

Rod harvesting is labour intensive and is

impractical for large areas. However, for smaller

plots, and where drying facilities are not

available, rod harvesting is far more cost effective.

Figure 6D1 gives an indication of the cost of

planting willow coppice per hectare.

The total

indicative cost is approximately €3,000 per

hectare. This includes for mechanical planting,

cuttings, fencing and weed control which is

important in the first year of growth. Planting

costs in Scandinavia are approximately €2,000

per hectare because their industry has established

a "critical mass" which ensures

economies of scale particularly with regard to

the cost of cuttings and the hire of mechanical

planters. As the industry develops in this country

we expect these establishment costs to fall.

Figure 6D2 shows the typical cost of maintaining

and harvesting the willows per rotation. The

harvesting cost depends on whether it is by

hand or by machine and on the volume i.e. a

large area, in excess of 10 hectares, harvested

by machine is likely to be around €600 per

hectare.

USING WILLOW AS A BIO-FILTER

Rural Generation Limited has developed the

use of willows as a bio-filter to treat dirty water

or effluent. In 1998 an EU research project was

set up a Culmore in Co. Derry to monitor the

effects of disposing of dirty water and sludge

onto willow coppice. Regulations for the disposal

of wastewater and sludge are becoming

stricter and environmentally acceptable options

must be found for dealing with these wastes.

Four hectares of short rotation coppice were

planted in May 1998 adjacent to Culmore Water

Treatment Works. This is a relatively large

treatment plant servicing the equivalent of

120,000 people. A ground water irrigation system

was installed consisting of 28mm diameter

pipes with holes at 8m centres. The flow of

effluent through the pipes is controlled by

pumps and motorised valves.

The site is divided into separate plots, one control

plot receives no irrigation, a second plot

receives irrigation with pure water, a third plot

receives the sludge, a fourth plot receives irrigation

with waste water at 1 times the potential

evapotransperation (PE), a fifth plot at 2 x PE

and a sixth plot 3 x PE The site was harvested

early in 2002 and yields were measured, as well

as chemical and microbiological ground water,

pests, disease and weed problems.

During harvesting the irrigation pipework was

only damaged twice and this was repaired easily.

Figure 6D3 summarises the results. The volumes

of NP & K were recorded as well as the

total volume of effluent, which was only

applied during the growing season.

Figure 6D4 indicates the yields from the various

trial plots. It is interesting to note that the

control plot which received no irrigation has in

fact yielded greater mass than the plots which

received 1 x PE waste water, 2 x PE waste water

and 1 x PE clear water. We do not have an

explanation for this.

One of the reasons why the site at Culmore was

chosen was because the water table in the

ground is only 60cm below ground level. When

monitoring the capability of the willows to

absorb nutrient we were particularly concerned

that effluent was not flowing through the willows

and entering the ground water. Therefore,

had we selected a site with a water table deep

below the surface we would have been unsure if

it was the willows or the ground filtering that

was absorbing the nutrients. By selecting a site

with a high water table we were able to establish

that no detectable levels of nitrate, phosphate

or heavy metals were entering the ground

water.

One of the reasons why the site at Culmore was

chosen was because the water table in the

ground is only 60cm below ground level. When

monitoring the capability of the willows to

absorb nutrient we were particularly concerned

that effluent was not flowing through the willows

and entering the ground water. Therefore,

had we selected a site with a water table deep

below the surface we would have been unsure if

it was the willows or the ground filtering that

was absorbing the nutrients. By selecting a site

with a high water table we were able to establish

that no detectable levels of nitrate, phosphate

or heavy metals were entering the ground

water.

Generally there was a trend towards greater

biomass yields as the volume of wastewater

irrigated rose. There are practical limits as to

how much effluent can be absorbed by willow

and potassium (P) is normally the limiting factor.

It is also likely that effluent with a

Biological Oxygen Demand (BOD) in excess of

500 can be adequately treated using willow as a

bio-filter.

HEAT FROM BIOMASS

This section is concerned with the combustion

of willow chip and wood chip in solid fuel boilers,

and also with the combustion of waste agricultural

products such as chicken litter and

spent mushroom compost.

Rural Generation Limited has taken on the Irish agency for Farm 2000 boilers. There are several

different boiler types within the range including

Big Bale boilers, High Temperature boilers

and automatic feed Swebo boilers.

|

| Big Bale, Multi fuel, Farm 2000 Boiler |

Big Bale boilers, as illustrated, were originally designed

to accommodate full size round bales. It is now

more usual to burn waste products such as timber,

cardboard or paper than to burn materials

that have a value such as straw.

The automatic feed Swebo boilers consist of a

full storage hopper, a combustion chamber and

a modified boiler. In automatic feed mode the

wood chips or willow chips within the hopper

are delivered to the round combustion chamber

by a screw auger. The rate of combustion and

the amount of heat produced can be regulated

by the auger speed. Full combustion takes place

within the ceramic pot, and a flame is then fed

into the boiler chamber, where the water is heated.

The automatic feed systems can also be operated

in manual mode, where the fuel is fed directly

into the boiler through the usual door. This

allows the operator to use a range of waste fuels

such as cardboard, paper, logs etc. While it is

labour intensive it can be cost effective if the

fuel has little or no cost. Figure 6D5 shows the

comparative cost of wood chips versus oil. For

example, if wood chips are being purchased at

€73 per ton, and heating oil is costing 34.5

cents per litre then the heating bill for a system

running on wood chips will be 54% of the comparative

bill for an oil fired systems.

It is worth noting that these costs are based on

wood chips with 30% moisture content.

However, the willow chips produced by Rural

Generation typically have moisture content of

approximately 10%. Therefore, the savings will

be greater because the calorific value of timber

rises as the moisture content falls. Taking the

€73/34.5 cents per litre oil scenario, for wood

chips at 10% moisture the comparative cost

would be 34% i.e. heating by wood chip would

be 34% of the cost of heating by oil.

Rural Generation Limited has recently installed

one of these boilers into an alcohol rehabilitation

unit in Co. Donegal. They run the system in

both automatic feed and manual feed mode

depending on the availability of labour.Rural

Generation also supplies willow chip to a community

centre in Derry. Another manufacturer

supplied the boiler in Creggan Community

Centre, but the quality of chip provided by

Rural Generation proved to be a better fuel than

anything else they could obtain.

A gasifer was built under a Non Fossil Fuel

Obligation (NFFO) contract at Brook Hall

Estate in Derry with a capacity of 95kWe and

200kWth. It has been producing heat and power

for the past six years.

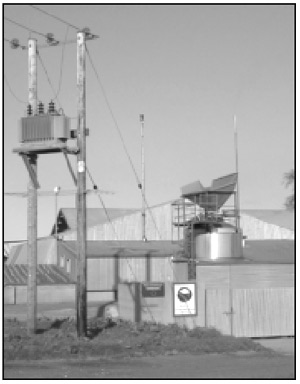

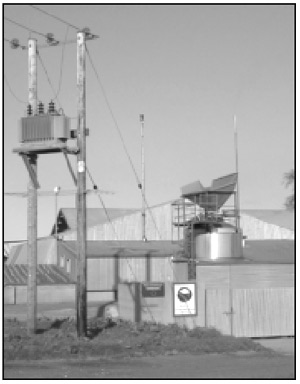

|

| Gasifier and Generator Building with Grid Connection,

Brook Hall Estate |

The gasifier has been

modified continuously as part of a managed

development programme and is now capable of

producing 200 cubic metres of wood gas per

hour. This wood gas is used to drive a diesel

engine that in turn is linked to a generator. The

generator produces electricity, which is exported

to the Northern Ireland grid via the transformer.

The gasifier comprises a 9cubic metre

stainless steel hopper, which holds wood chip

or willow chip. This feeds a down draft gasifier

that is linked to an Iveco diesel engine. The system

runs in batch mode and typically operates

for 12/14 hours per day producing electricity

and thermal energy. The thermal energy (hot

water) is used to dry cereals on the 400-hectare

Brook Hall Farm. The heat is also used in the

winter months to dry willow chip that will subsequently

be used in the gasifer.

The capital cost of the gasifier is approximately

€2,000 per kW. This includes containerised

units, hopper, control system, electricity generating

system, safety mechanisms, heat exchangers

on the engine exhaust and the engine cooling

system and all installation and commissioning.

The cost does not include for structural

modifications to accommodate the CHP unit,

compressed air supply, fuel storage silo or grid

connection costs.

LOOKING AHEAD

I have already discussed the work that Rural

Generation has done with regard to bio-filtration,

heat and power generation from willows

and heat only applications. We are however

continuing to push forwards to find holistic

solutions to other problems.

Northern Ireland produces approximately

200,000 tonnes of spent mushroom compost

every year. This is becoming increasingly difficult

to dispose of, as the traditional route of

land spread becomes less viable due to legislative

changes. Rural Generation has developed a

system for co-combusting spent mushroom

compost with dried willow chip. The heat generated

can then be recycled to heat the mushroom

house.

Spent mushroom compost typically has a 80%

moisture content. Virtually all other attempts to

reduce this moisture content to a level at which

the compost will satisfactorily burn, (usually

about 40%), have required a greater energy

input than is subsequently derived from the

combustion. I.e. you have to expend more energy

to reduce the moisture content than the compost

subsequently produces on combustion.

Rural Generation has found a solution to this

problem.

Rural Generation has also successfully combusted

chicken litter in their boiler systems.

Tests are now going on to ensure that emission

levels, particularly of ammonia, are reduced to

an acceptable level. Rural Generation has also

been involved in trials using "fine" willow chip

as a bedding material in chicken houses. While

this is still at an experimental stage early indications

are that the salicylic acid in the willow

can substantially reduce the amount of ammonia

in the chicken litter. This is always a prime

concern for chicken farmers who are trying to

reduce "hock burn" by keeping levels of ammonia

as low as possible. If our tests are successful

this will open up a new market for willow

chip. The chicken industry in Northern Ireland

currently relies on imported wood shavings for

the bulk of its litter.

The future lies in integrated environmental

solutions and not in energy alone. Rural

Generation believes that while the production

of willow as an energy crop can generate profits

for the farmer of the order of €250 per

hectare, the profitability of the venture is

enhanced significantly when the coppice has

supplemental use.

|

| Willows ready for harvest |

If short rotation coppice is

used as a bio-filter for sewage sludge the profit

margins are likely to be increased significantly.

Similarly if willow chip is used as chicken litter

the value of the chip is likely to be greater than

the market value for chip as a fuel which is currently

around €65 per ton.

We believe that farmers and commercial growers

should look at all the options which willows

offer before committing to a course of action.

Traditionally farmers have produced a product.

They deliver the product to the farm gate and by

the time that product has reached the consumer

it will have increased in value or cost by a factor

of around 4. If farmers commit the same sin

when producing willow, by stopping at the first

interface in the supply chain they will prevent

themselves from maximising value from their

product. This is probably the most difficult

aspect of willow cultivation for farmers to

grasp. They are comfortable with production

only scenarios. They need to increase their

involvement in the supply chain to maximise

returns and to add value to what is a relatively

simple product.

|

This is one of almost 50

chapters and articles in the 336-page large format book, Before the Wells

Run Dry. Copies of the book are available for £9.95 from Green Books. |

|

Continue to part E of Section 5: The case for returning to real live horse power

Sitemap for Before the Wells Run Dry

One of the reasons why the site at Culmore was

chosen was because the water table in the

ground is only 60cm below ground level. When

monitoring the capability of the willows to

absorb nutrient we were particularly concerned

that effluent was not flowing through the willows

and entering the ground water. Therefore,

had we selected a site with a water table deep

below the surface we would have been unsure if

it was the willows or the ground filtering that

was absorbing the nutrients. By selecting a site

with a high water table we were able to establish

that no detectable levels of nitrate, phosphate

or heavy metals were entering the ground

water.

One of the reasons why the site at Culmore was

chosen was because the water table in the

ground is only 60cm below ground level. When

monitoring the capability of the willows to

absorb nutrient we were particularly concerned

that effluent was not flowing through the willows

and entering the ground water. Therefore,

had we selected a site with a water table deep

below the surface we would have been unsure if

it was the willows or the ground filtering that

was absorbing the nutrients. By selecting a site

with a high water table we were able to establish

that no detectable levels of nitrate, phosphate

or heavy metals were entering the ground

water.